Copyright © Chang Zhou Three Superman New Material Co., Ltd. All Rights Reserved. Site Map

- +86-15061119570

- plh3026@hotmail.com

- No. 181 Yangang Road, Jintan District, Changzhou, Jiangsu Province

Founded on November 26, 2019 and situated in Jintan District, Changzhou City, Chang Zhou Three Superman New Material Co., Ltd. is an enterprise dedicated to the R&D and production of multi-layer composite materials, including TPE, TPO, TPV, PP composite sheets, PP-GF extruded glass fiber sheets, and PP honeycomb sheets. The registered capital for its first phase stands at RMB 3 million.The company obtained ISO 9001 Quality Management System certification in 2020.

In 2023, it invested in new extrusion lines to expand its product range and boost production capacity.

To support customers with pre-production product prototyping and batch OEM manufacturing of finished parts, the company introduced large-scale blister forming equipment (3300mm * 2300mm) in 2024. This equipment enables the production of large blister components with a net dimension of 3000mm * 2200mm.

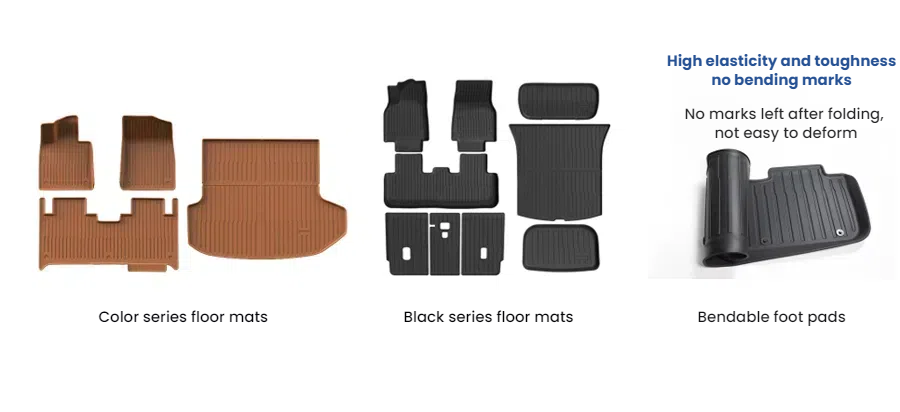

In a bid to help customers reduce production costs, the company will collaborate with clients to produce TPE floor mat sheets in Lishui, Zhejiang Province in 2025. Mass supply to customers will commence within one month of the completion of equipment installation and commissioning.

The company's founder has over 30 years of in-depth experience in the extruded sheet industry, with expertise spanning production, technology, and sales—accumulating extensive R&D knowledge and market resources. Most team members boast more than 10 years of professional experience in sectors such as automotive interiors. With such strengths, the company is fully capable and confident in delivering high-quality development and application of various materials.

Product and Pricing Advantages: Most of the company's products are developed and manufactured in-house through self-modification, eliminating intermediate links. This not only ensures superior product quality but also enables more competitive pricing.

Product Introduction

1. TPE/TPO/TPV Sheet:

Whether you need a soft touch or high-strength support, our TPE products offer the perfect match!

🔹 Comprehensive hardness coverage for worry-free application

Soft-Flex Series: 75A-83A – Suitable for products requiring exceptional flexibility and flex resistance, instant rebound after opening, or vacuum packaging.

Standard Series: 90A (32D)-38D – Suitable for most popular products.

Hard Series: 45D-50D – Suitable for applications such as door sills or where high rigidity is required, as well as load-bearing and wear-resistant applications such as industrial components and automotive parts.

🔹 Flexible Density Customization

From lightweight to high density, we can adjust material density to meet your needs, optimizing the balance between product performance and cost!

🔹 Free Choice of Colors and Textures

Choose from 25 colors and ten different patterns for the interiors of major domestic automakers!

🔹 Why Choose Us?

✅ Highly adaptable: Hardness, density, pattern, and color are all customizable.

✅ Low odor, high matte finish, low VOC, with a nationally recognized laboratory report.

✅ Suitable for various processing methods, including die sets, punches, and automated and manual production lines.

2. TPE/TPO+XPE+plasticized cloth or burr cloth composite

3. PP composite board/PE board (GF can be added)

Graphic introduction

Compared to PET felt, it offers advantages such as lower price, better sound insulation, no leakage, no mold, and easy cleaning.

4. Extruded Fiberglass Sheet

The image below shows a custom-molded spare tire cover using our product as the outer skin and EPO foam in the center.

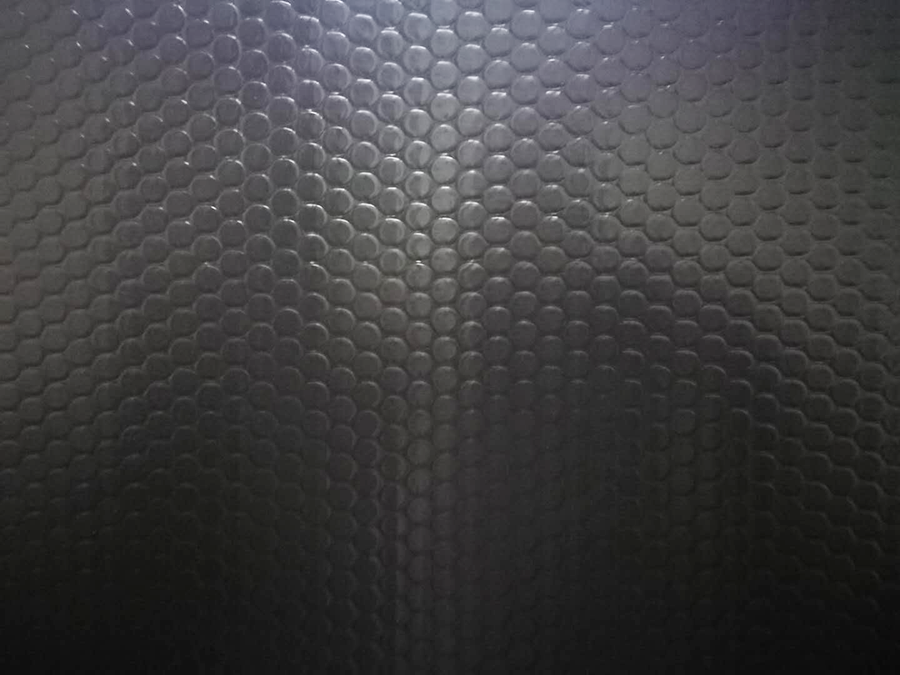

5. Dot honeycomb panel

Car spare tire covers, commercial vehicle roof projects, and other applications: packaging boxes.

Product front view

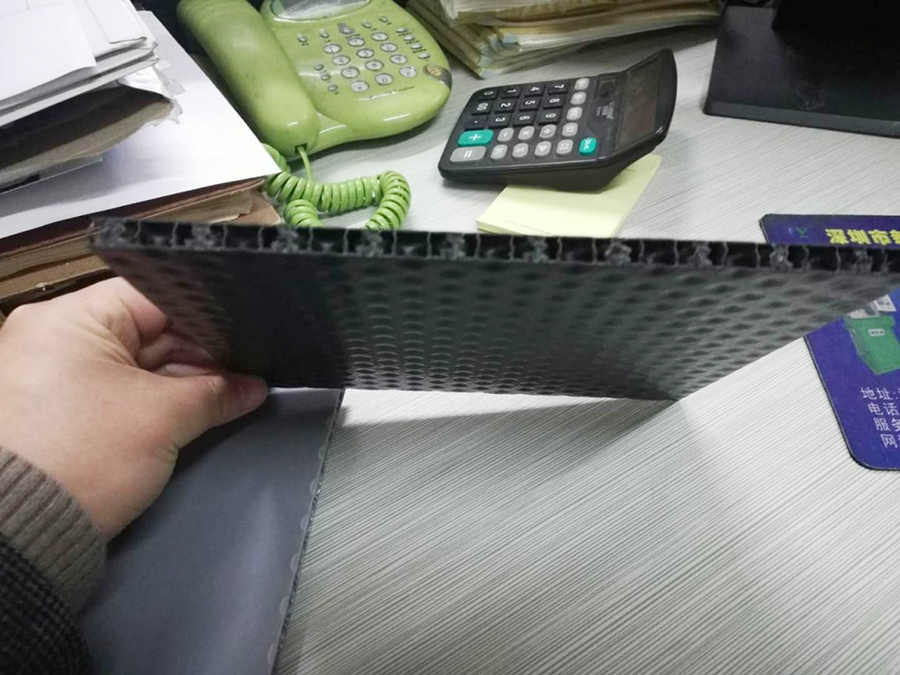

Product side view